In 2014, HEGER designed a steel floating drydock based on parameters provided by PACIFIC SHIPYARD INTERNATIONAL (PSI). The dock was designed to meet the requirements of the American Bureau of Shipping for lifting vessels displacing up to 7,500 long tons. The dock was also designed to be capable of obtaining NAVSEA certification under MIL-STD 1625D requirements.

The dock’s design vessels were considered to be the USCG National Security Cutter and the US Navy’s LCS-2 class vessel, among others.

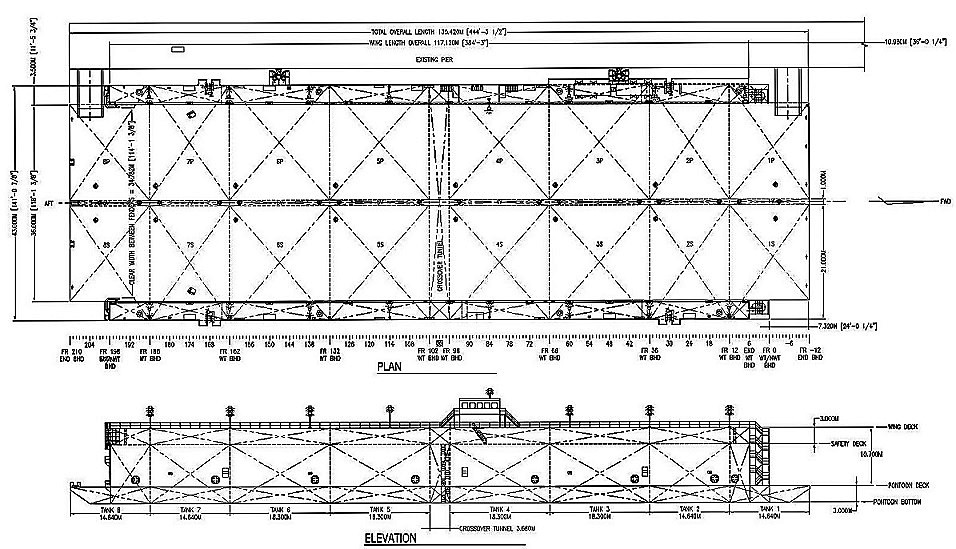

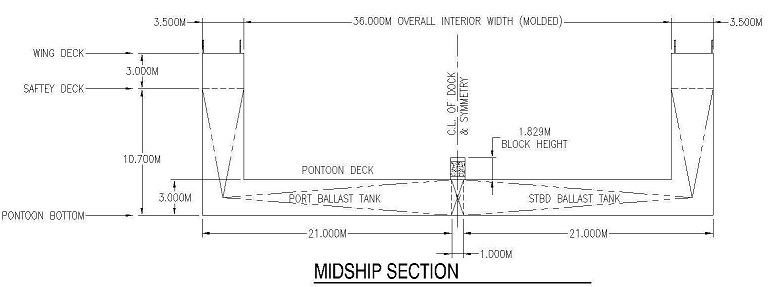

The floating drydock design included naval architecture evaluations, structural designs, equipment sizing, layouts and schematics for various mechanical and electrical components. Notable outfitting items included a translation system, vehicle access bridge, pedestrian gangways, utility service connections, stormwater collection tanks, etc.

HEGER’s dock design package included design drawings, specifications, and an operating manual with architectural, structural, mechanical, electrical, and HVAC details.

After being built in 2017 by CHENGXI SHIPYARD CO., LTD. in China, the dock was classed by ABS and delivered to PSI’s shipyard facility in Honolulu, Hawaii aboard a heavy lift vessel.

The dock was put into service in late 2017 and has since docked a vessel equal to its maximum lift capacity as shown in the video below: