A mooring system is a crucial component of a floating dry dock facility. Most shipyard facilities require a rigid, fixed mooring system which keeps the dock in position, affixed to the pier or dolphins, in the most extreme heavy weather conditions but these system must also provide the flexibility for the dock to trim and list during docking and undocking evolutions. For facilities in high seismic zones, the rigid moorings have to be designed to keep the dock, and vessel in dock, safe in the event an earthquake occurs.

HEGER has extensive experience in designing over 40 mooring systems for floating dry dock facilities, across the USA and overseas, for both new designs and retrofits. Each mooring system is customized to a facility’s specific parameters such as pier geometry and capacity, maximum geographic wind and current, design vessels, operability, seismic accelerations, etc.

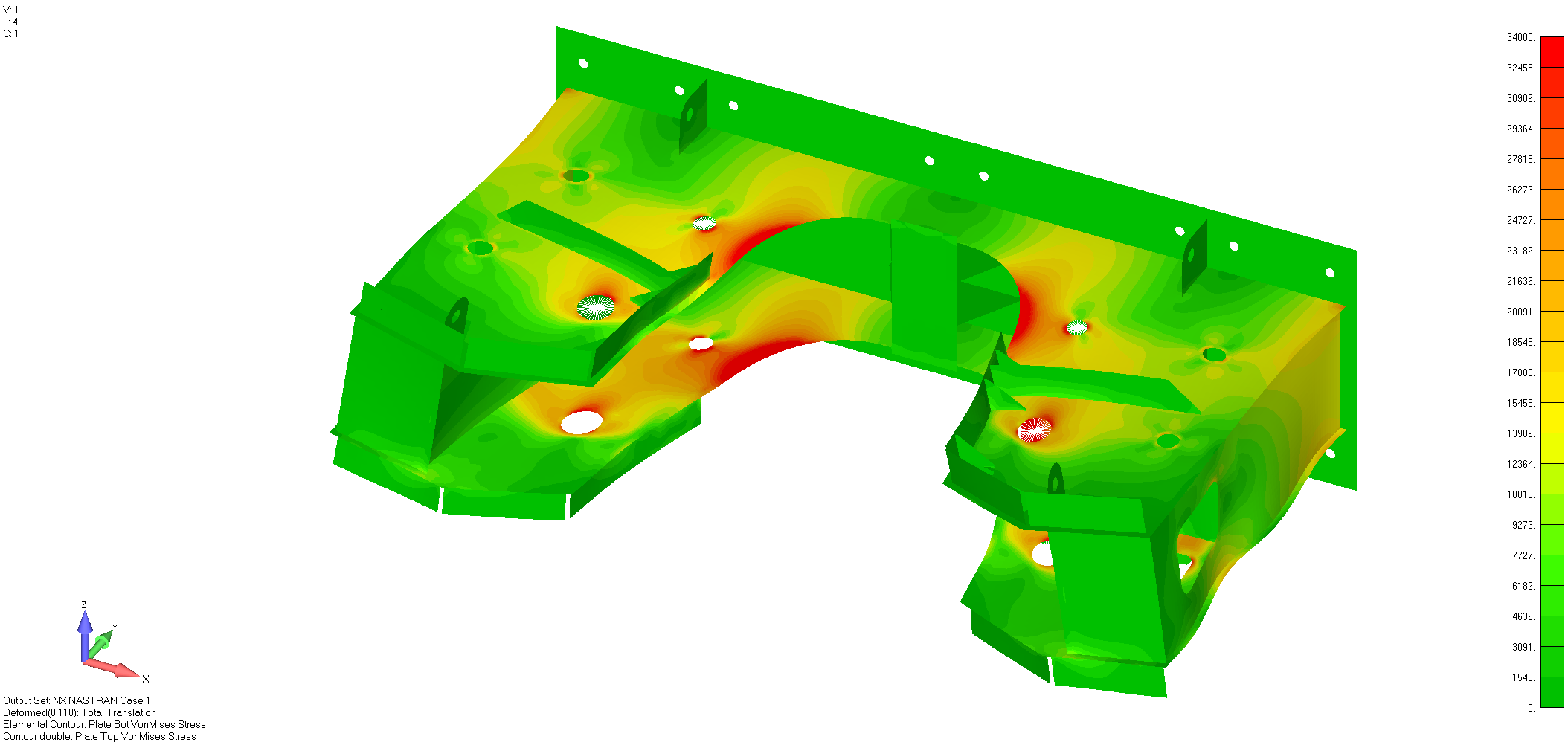

The mooring points are designed to withstand a high concretion of loadings generally ranging from 250 tons to as high as 1,000 tons. HEGER utilizes state of the art Finite Element Analysis (FEA) computer programs to ensure these highly customized structures have adequate capacity to safely withstand the expected loadings.

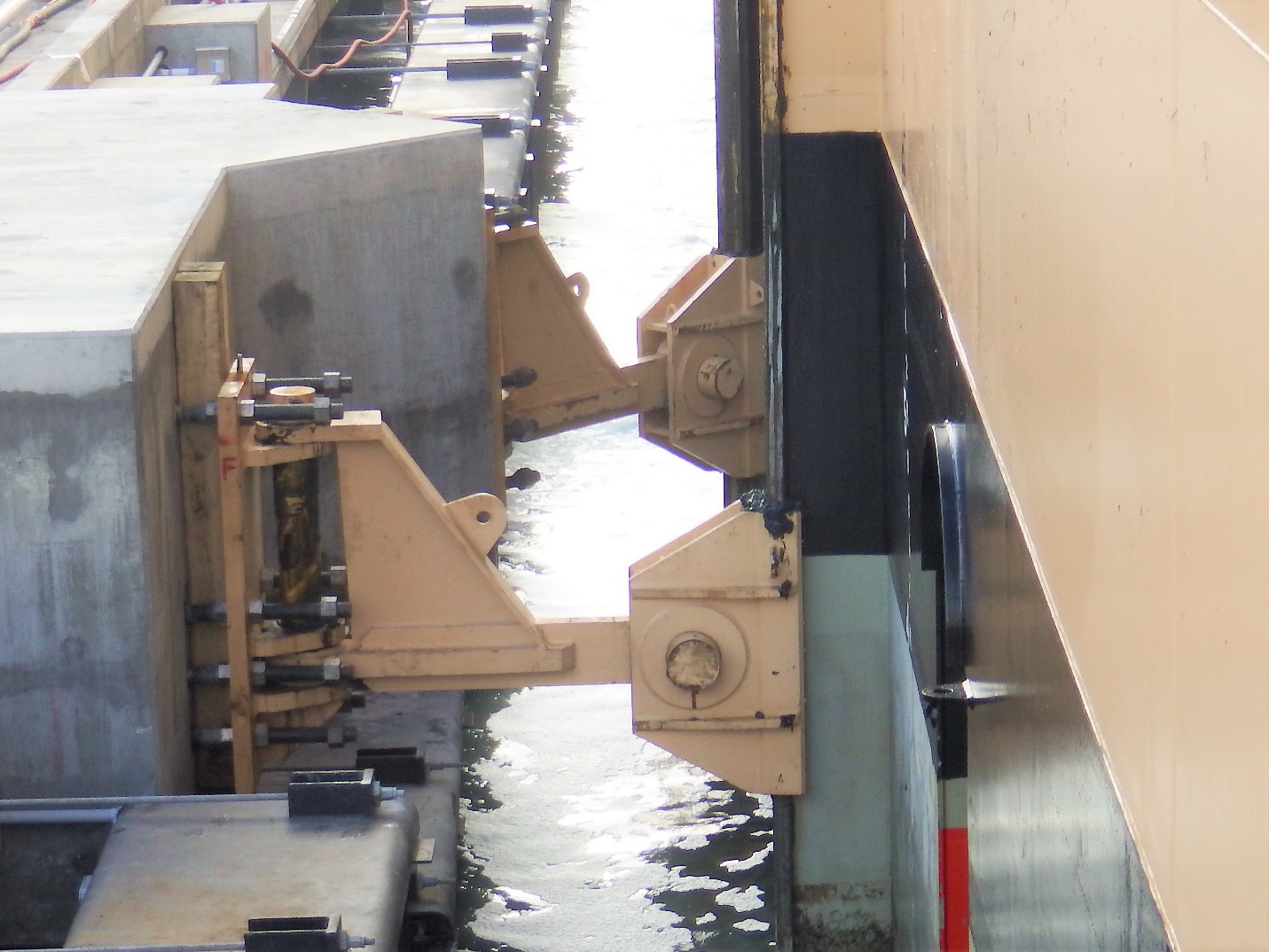

The mooring systems HEGER designs can be categorized into either a “Tee” type or “Quick-Disconnect” type mooring system. Generally, HEGER recommends the “Quick-Disconnect” type mooring system for docks which are required break from its mooring location frequently which may be the case if the dock has to translate to its submergence berth or is utilized in transfer and launch operations. For all other facilities, HEGER would generally recommend a “Tee” type system.