In 2016, HEGER designed a steel floating drydock based on parameters provided by HUNTINGTON INGALLS INDUSTRIES (HII). The dock was designed to meet the requirements of the US Navy’s MIL-STD 1625D and the American Bureau of Shipping for lifting vessels displacing up to 70,000 long tons. The dock was also designed with removable wing walls and the ability to side transfer vessels built on shore to the dry dock for launch. The dock is outfitted with a translation system which allows the dock to navigate between the transfer berths at the shipyard and the dredged submergence basin.

The dock’s design vessels were considered to be the LHD/LHA hull, LPD-17, DDG-51, and CG-47 class vessels.

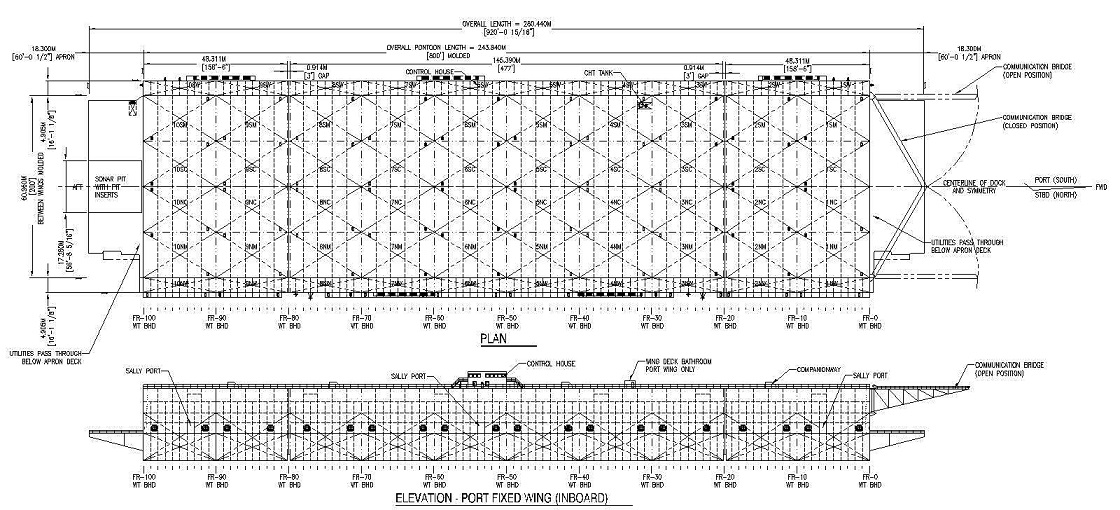

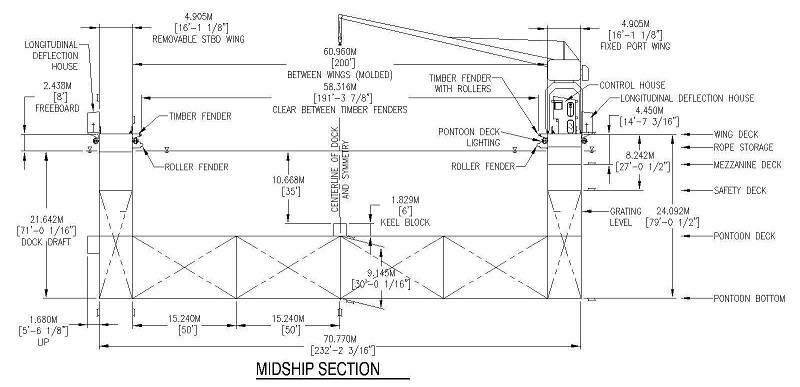

The floating drydock design included naval architecture evaluations, structural designs, equipment sizing, layouts and schematics for various mechanical and electrical components. Notable outfitting items included a quick-disconnect type mooring system, vehicle access bridge, transfer car bridges, pedestrian gangways and communication bridge, utility services, translation system, wingwall cranes (not designed by HEGER), various collection tanks, etc.

The dock design package included design drawings, specifications, and an operating manual with architectural, structural, mechanical, electrical, and HVAC details.

HEGER also assisted HII in developing a Facility Certification Report (FCR) which was submitted to NAVSEA for review prior to commissioning and certification.

After being built in 2019 by Qingdao Beihai Shipbuilding Heavy Industry Co., Ltd. In Qingdao, China, the dock was delivered in three pieces to Pascagoula, MS aboard a heavy lift vessel.

After the dock was assembled and installed in its mooring gripes the dock was certified by NAVSEA and put into service in 2019.